| WHAT YOU GET: |

|---|

|

1 x UNIMIG WORKSHOP 425 SWF MIG WELDER (with Life Time After Sales Machine Support)

|

|

1 x KT50 SWF Unit

|

|

FREE: 15kg Roll of Wire

|

|

1 x 4m SB36 MIG Torch (including consumables)

|

|

1 x 4m Twist Lock Electrode Holder

|

|

1 x 400 Amp Earth Clamp & Lead

|

|

1 x Twin Gauge Argon Regulator

|

|

1 x 2m Gas Hose Complete with fittings

|

|

1 x Operating Manual

|

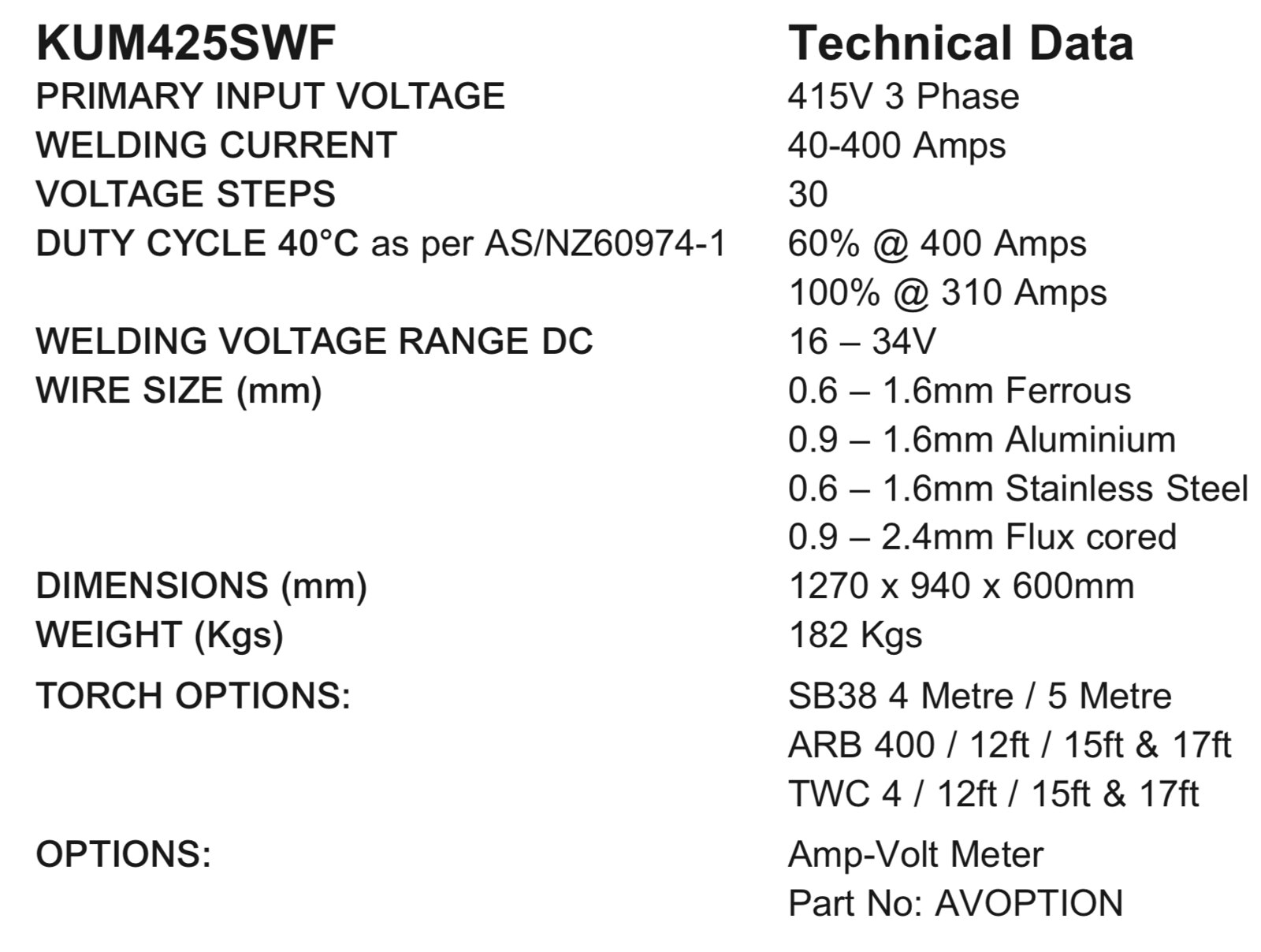

UNIMIG WORKSHOP 425SWF

The UNIMIG 425 SWF is a powerful high-duty cycle machine designed for medium to heavy fabrication and rural applications. Combining smooth arc characteristics with complete reliability, the UNIMIG 425 SWF is the unit to satisfy all the demands of the professional welder. Features a completely enclosed KT50 wire feed unit which helps prevent dust and moisture from fouling your wire and contaminating your weld. Fitted standard with a geared four roller drive system ensuring consistent wire feed and smooth welding. It comes with fully covered 10 Metre interconnecting cables and wheels for increased maneuverability.

BUILT TO LAST

Designed and manufactured with the best quality components for increased durability and reliability. Workshop series machines feature

Copper wound transformer and smoothing choke, large 300mm cooling fan with enclosed motor, to maximise cooling for high duty cycle operation.

30 position switching, allows precise setting in small increments of welding voltage so the operator can achieve the correct weld penetration.

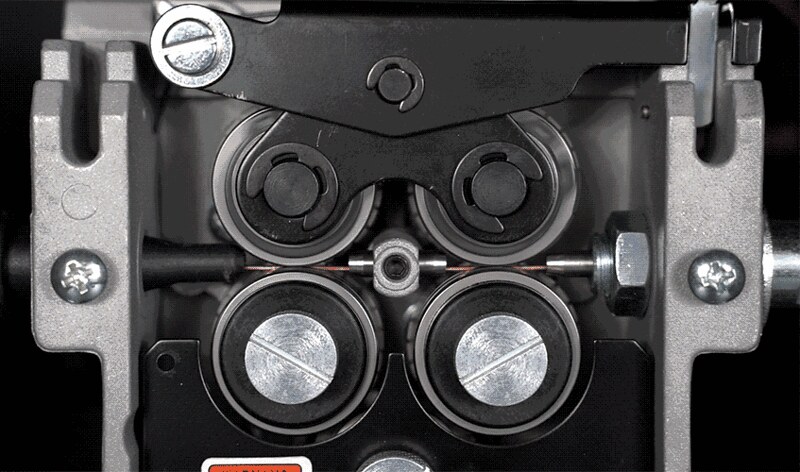

Geared four roller drive unit, featuring 40mm drive rollers for consistent smooth wire feed.

| FEATURES: |

|---|

| – The UNIMIG 425 SWF is a powerful high-duty cycle machine designed for medium to heavy fabrication and rural applications. |

| – Combining smooth arc characteristics with complete reliability, the UNIMIG 425 SWF is the unit to satisfy all the demands of the professional welder. |

| – 30 position switching, allows precise setting in small increments of welding voltage so the operator can achieve the correct weld penetration. |

| – Features a completely enclosed KT50 wire feed unit that helps prevent dust and moisture from fouling your wire and contaminating your weld. |

| – Fitted standard with a geared four roller drive system ensuring consistent wire feed and smooth welding. This also assists with using longer MIG Torches. |

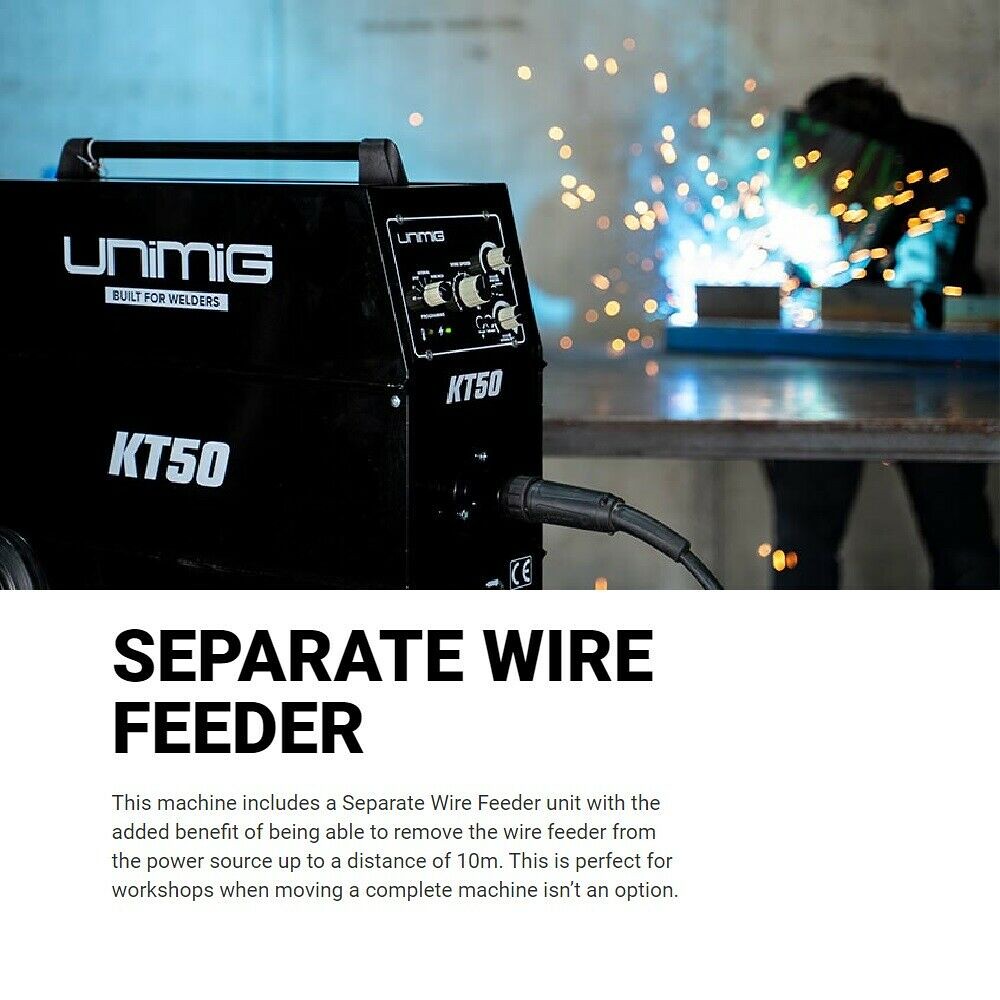

| – Comes with a fully covered KT50 Separate Wire Feeder which covers you an extra 10 metres, giving you increased manoeuvrability. This is perfect for workshops when moving a complete machine isn’t an option. It also prevents dust and moisture from fouling your wire with its smart enclosed system design meaning no contaminates in your welds. |

| – Copper wound transformer and smoothing choke. |

| – Large 250mm cooling fan with enclosed motor, to maximise cooling for high-duty cycle operation. |

| – Thermal Overload Protection |