We are your leading distributor of plasma cutters for welding. We have a range of plasma cutting machines from small portable units to large industrial models.

Plasma Cutters

We Offer A Wide Range Of Plasma Cutters

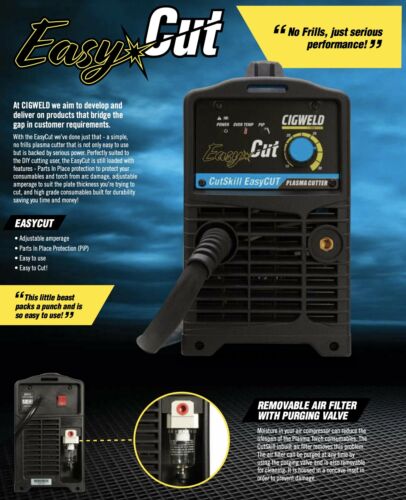

Our team are experts at all types of welding processes and can help you choose the right plasma cutters for your application. We offer a wide selection of quality products that will suit any budget. Whether you need a new product or just looking for some advice on how to get started with welding, we’re here to help. Our friendly staff are always available to answer questions and provide expert advice.

Frequently Asked Questions

A plasma cutter uses electricity to create an arc between two electrodes. The arc heats up the metal so much that it melts into a liquid state. The molten metal flows down toward the base plate until it cools and solidifies again. The result is an extremely hot piece of metal that has been cut out of the original material.

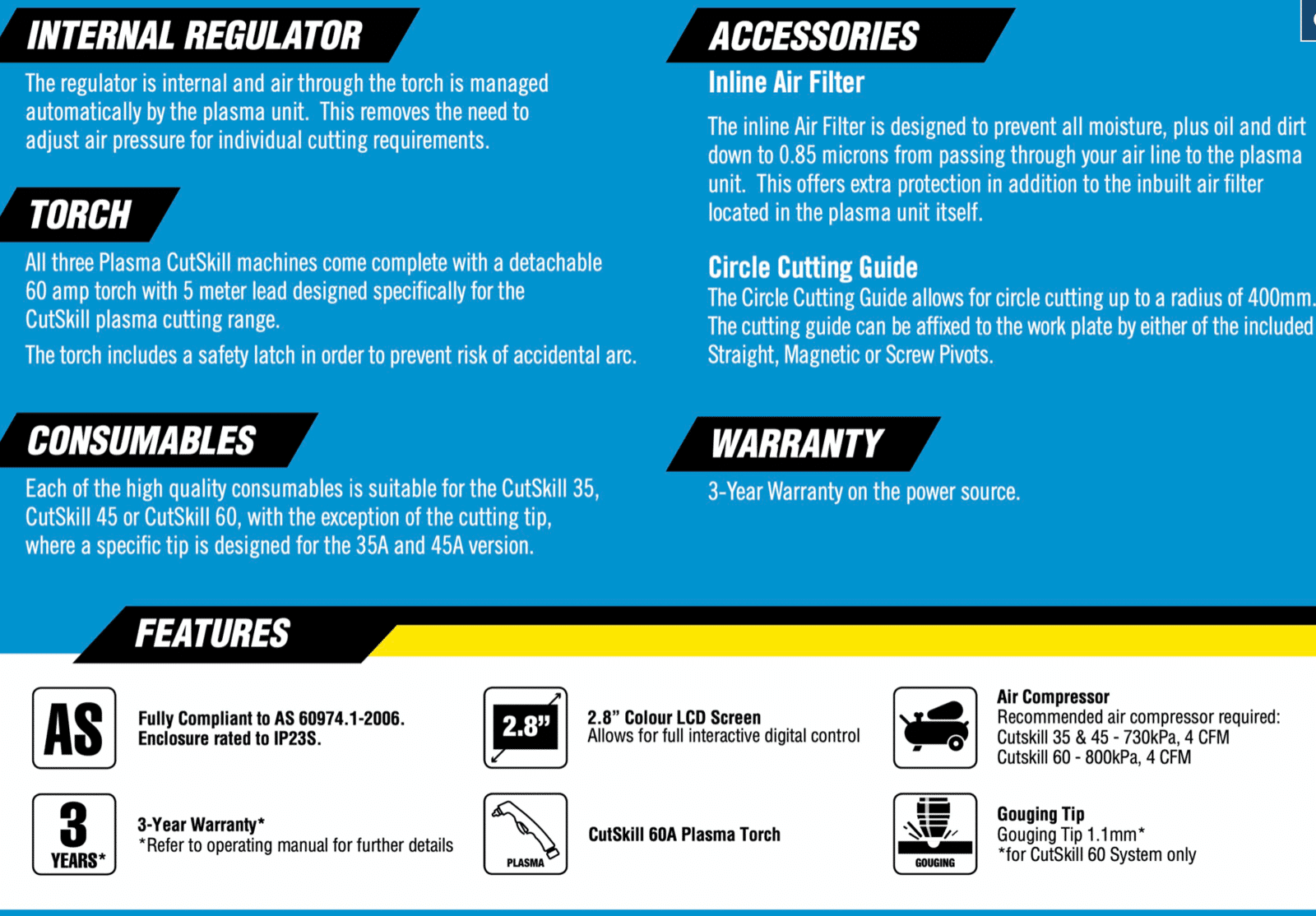

The proper breaker size will depend upon which type of power supply you use. For an inverter-based model, you need a 15 amp circuit breaker; for direct current (DC) models, you’ll need either a 20 amp or 30 amp circuit breaker.

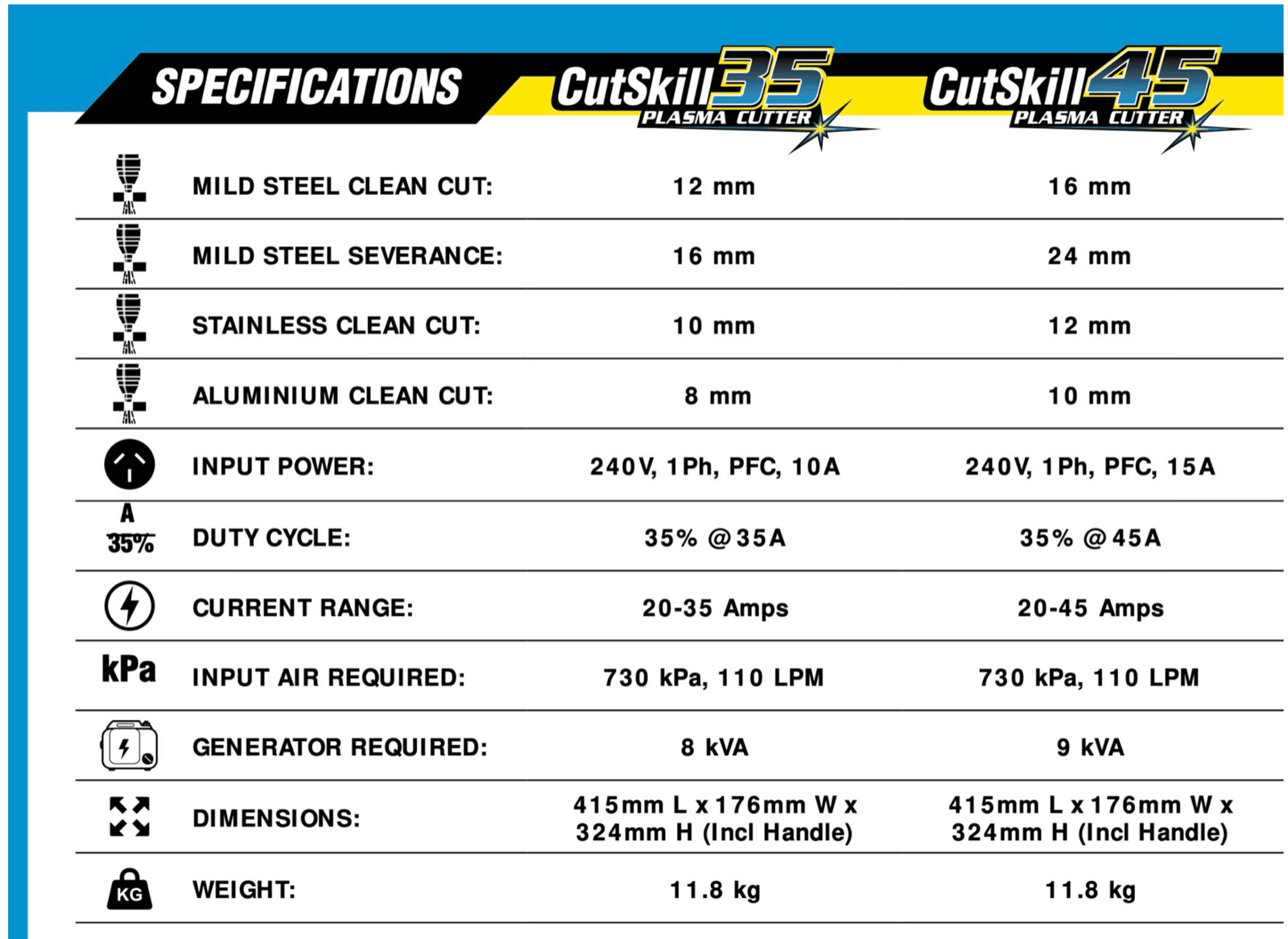

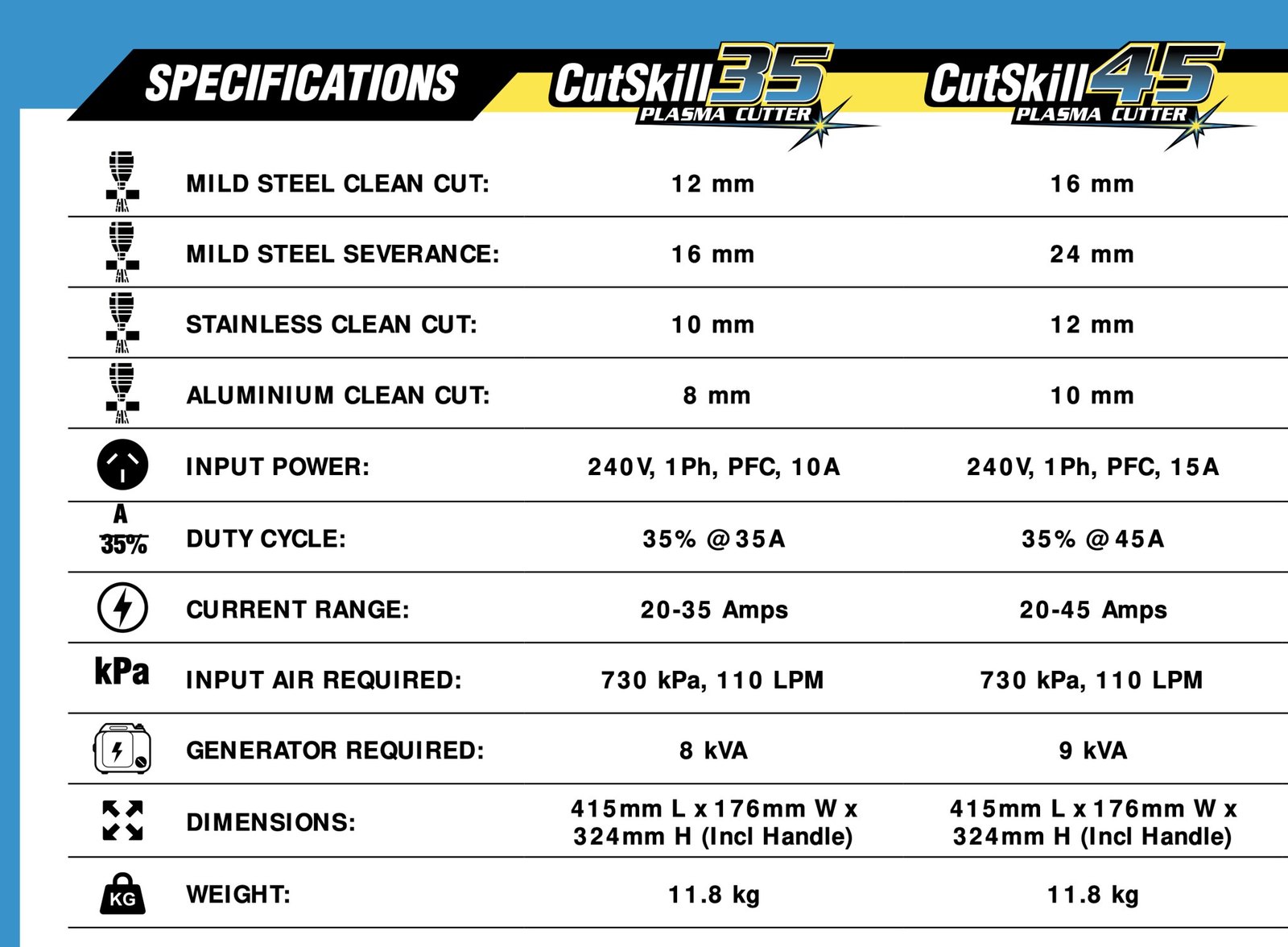

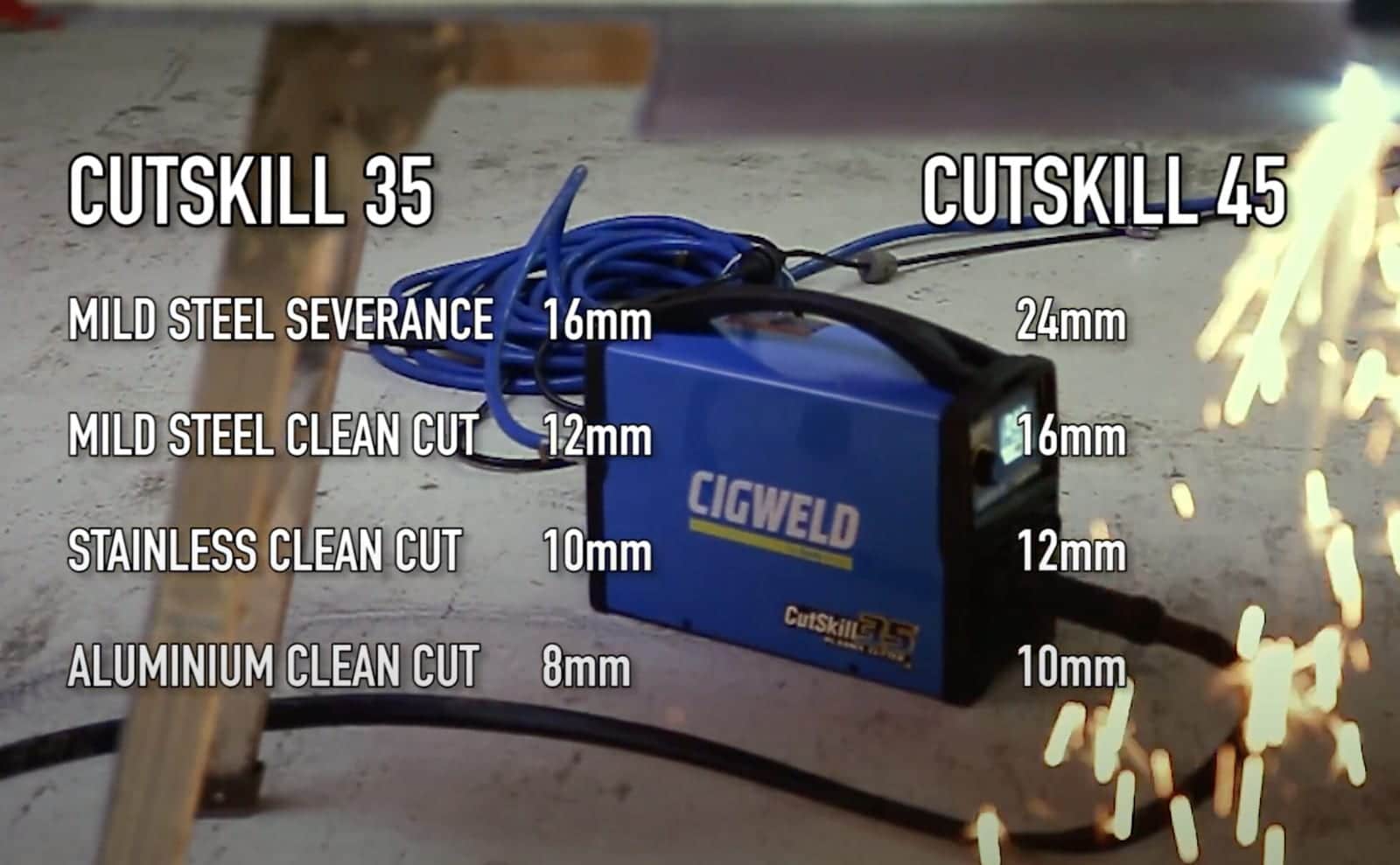

When selecting a plasma cutting machine, one must first determine which material to cut. The most common metal used in plasma cutting is steel, but other metals such as aluminium, copper, brass, magnesium, titanium, and zinc may be more appropriate depending on the application.

A plasma cutter is used primarily for cutting metal workpieces. It uses an electric arc to create extremely hot gases that cut through material very quickly. A plasma torch will be able to cut through almost anything with ease. A blowtorch will use compressed air to burn away material.

A small plasma cutting torch will require a 3/8″ diameter compressed air hose while larger tools will require 1-inch hoses. Hose size does not matter much when buying a gas-powered plasma cutter because most models include an adapter that connects to smaller-sized hoses.

The size of the air compressor doesn’t matter much either since all plasma cutters use at least 20 psi pressure and most cut up to 80 psi.