- Powerful Workshop Machine

- Separate Wire Feeder unit

- Cast Iron, Stainless Steel And Low Hydrogen

- Added MMA welding capability

- Four Geared Roller Drive Unit

- The Highest Quality Of Welds From UNIMIG’s Range

| What You Get: |

|---|

|

1 x RAZOR 500 SWF MIG/TIG/STICK Welder – (with Life Time After Sales Machine Support)

Please note, it is standard that these welders do not come with a plug. We will supply and fit the plug before we ship, so allow a day to do this before shipping.

|

| 1 x RWX8000 Automatic Welding Helmet |

|

1 x Separate Wire Feeder Unit

|

|

1 x 4m SB38 MIG Torch

|

|

1 x 10m Interconnecting Cables

|

|

1 x 10m Twist Lock Electrode Holder

|

|

1 x 500 Amp Earth Clamp & Lead

|

|

1 x Twin Gauge Argon Regulator

|

|

1 x 2 Metre Gas Hose Complete with fittings

|

|

1 x Operating Manual

|

|

PLUS Plug Fitted to Customer Specifications:

10 Amp / 20 Amp / 32 Amp / Custom Plug (please email us)

|

| Features |

|---|

| The RAZOR™ 500 SWF is a powerful workshop machine with MIG, TIG and STICK welding functions. |

| There is also support for both gas-shielded MIG and gasless MIG wire. There is no need to swap between machines, saving you time and setup. |

| This is an industrial machine equipped with a separate 4-wheel gear driven wire feeder and 10m interconnecting cables. |

| The MIG function allows you to weld with solid and Flux Cored Gasless wires. |

| Adjustment of Voltage & Wire Feed at the wire feeder makes for easy setting of welding parameters and gives the convenience of remote adjustment from the power source. |

| This machine features the added flexibility of a Separate Wire Feeder unit, allowing up to 10m of extra manoeuvrability in the workshop. |

| Crater current setting delivers perfect finishing of the weld, the electronic inductance offers fine adjustment of the arc characteristic and burn back adjustment leaves the wire stick out ready for the next weld. |

| Wire inch and gas check provide set up of wire feed and gas setting without any waste of wire or gas. |

| Added MMA welding capability delivers easy and high-quality welding using electrodes, including cast Iron, stainless steel and low hydrogen. |

| Three phases 415V power. |

| Four geared roller drive units provide the most consistent and smoothest wire feed. This also assists with using longer MIG Torches. |

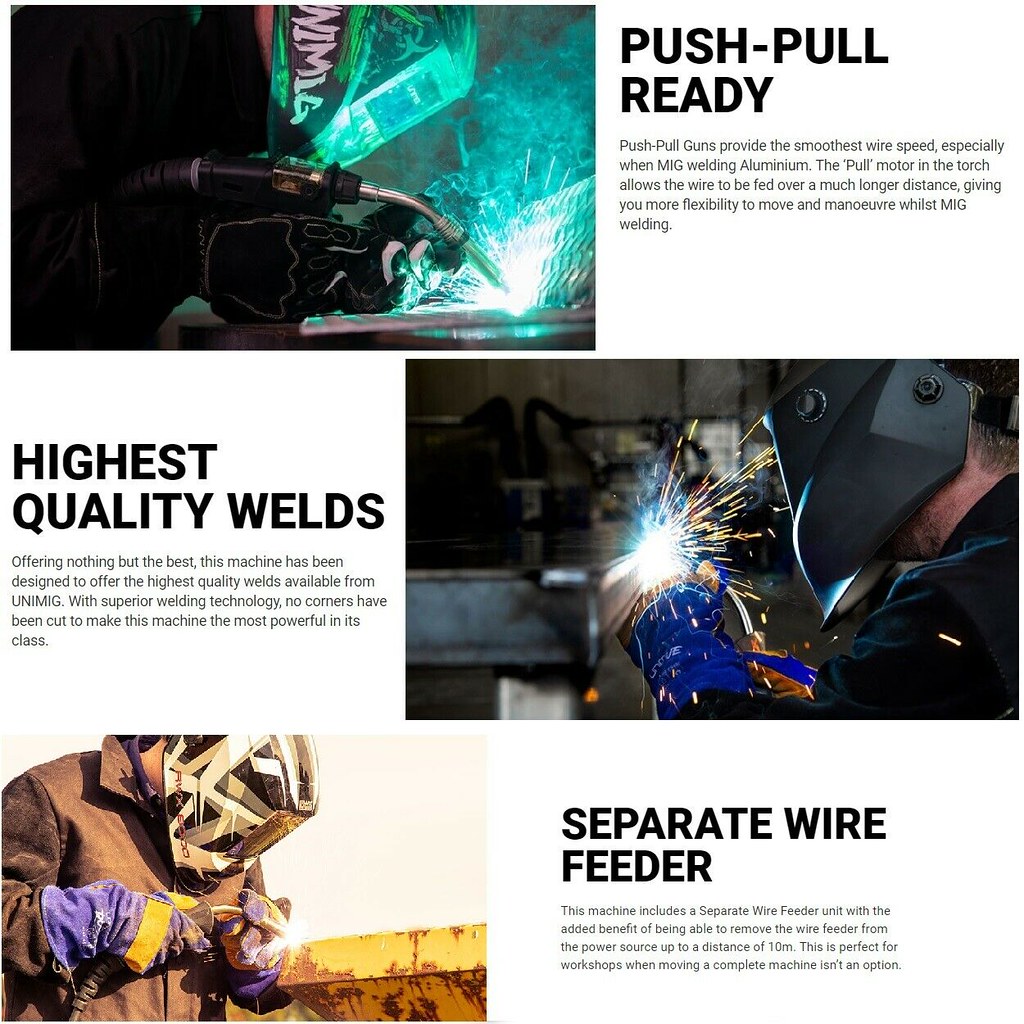

| Spool Gun and Push-Pull Gun ready, providing MIG welding capabilities across every spool size. |

| Push-Pull Guns provide the smoothest wire speed, especially when MIG welding Aluminium. The ‘Pull’ motor in the torch allows the wire to be fed over a much longer distance, giving you more flexibility to move and manoeuvre whilst MIG welding. |

| They are designed for superior performance and manoeuvrability, offering the highest quality of welds from UNIMIG’s range. |

| Ideal for heavy and structural welding applications, general engineers, maintenance workshops and rural workshops. |

| Built with a solid construction, this machine is designed to withstand the toughest conditions. |

|

Specifications Welding Helmet

|

|

This helmet features a 1/1/1/1 classification, the highest possible classification for optical clarity.

|

|

4 Arc Sensors maintain constant sensing and automatically switch the helmet from light to dark and back again

|

|

3 x Memory Functions – Store different shade, sensitivity and delay options into three easily accessible pre-sets.

|

|

Enhanced Viewing Area offers a larger viewing area for the operator.

|

|

True Colour High Definition Filter Technology greatly improves the optics allowing the user to see a full spectrum of colours. It also Assists with alleviating eye fatigue making it safer for extended periods of welding

|

|

Grind Mode allows the operator to switch the helmet from the welding mode into a fixed shade for grinding. This function removes the need for the operator to change visors and to simply use the welding helmet for grinding when required.

|

|

Shade Control Automatic Welding Lens allows the operator to switch between variable welding shades from 5-9 and 9-13.

|

|

Permanent complete protection against UV/IR even in transparent conditions. The UV/IR protection level is DIN15 all the time. Din standard approval guarantees maximum eye protection during welding.

|

|

Dark shade can be adjusted from shade 5-9 and shade 9-13 this makes it ideal for Gas cutting, Plasma cutting, Low amp TIG operation and MIG welding.

|

|

The unique shape design helps channel welding fumes away from the helmet and face area.

|

|

Automatic sleep mode shuts LED off when the helmet is placed into its storage bag or in darkness for battery conservation.

|

|

The front cover lens provided is manufactured of high polymer materials, is wear-resistant, thermostable, and resistant to spatter.

|