| WHAT YOU GET: |

|---|

|

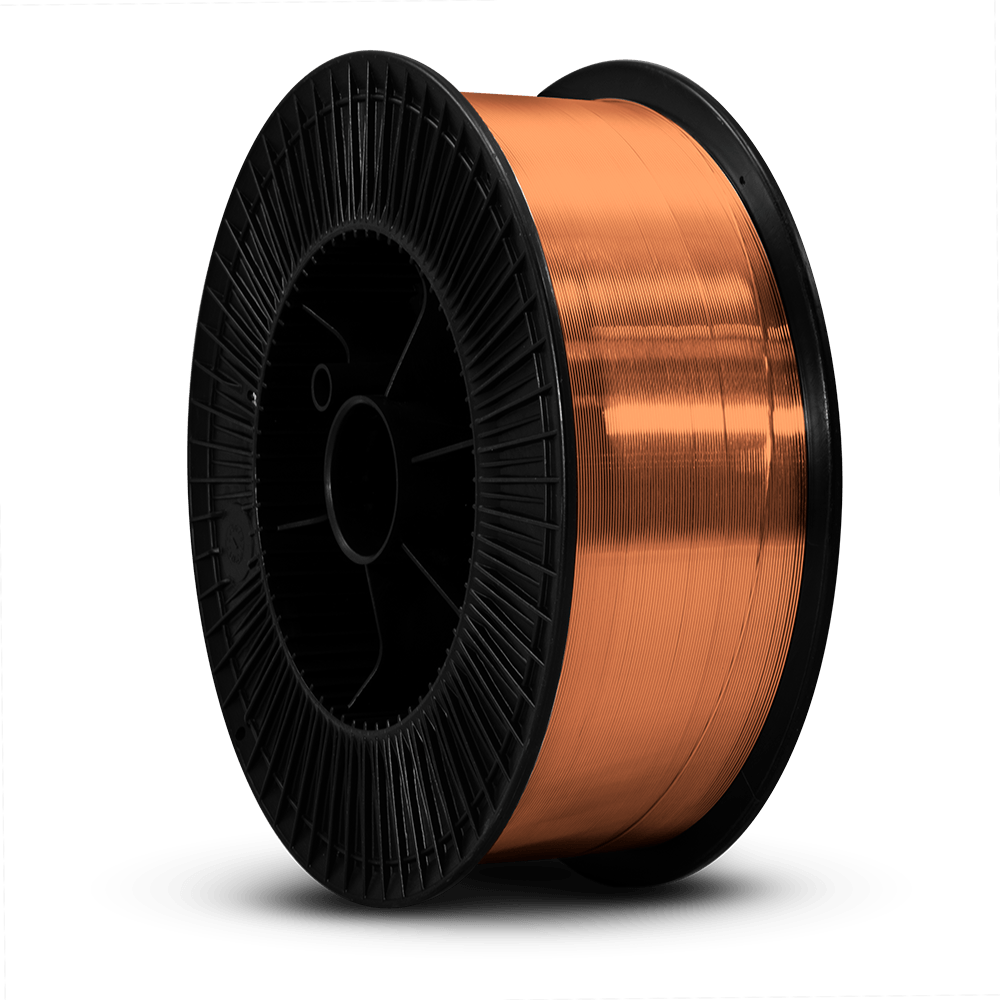

UNIMIG ER70S-6 MIG Welding Wire

|

|

Choose Your Wire Size

0.6mm / 0.8mm / 0.9mm / 1.0mm / 1.2mm / 1.6mm

|

|

Choose Your Wire Spool Weight

1kg / 5kg / 15kg

|

Unimig Solid Steel Welding Wire

UNIMIG ER70S-6 is a high-quality, copper coated, triple de-oxidised solid MIG welding wire supplied on 15kg / 5kg and 1Kg Plastic Spool. UNIMIG ER70S-6 is a mild steel welding wire that contains higher levels of manganese and silicon than other standard grades of MIG wire to produce high-quality welds when used on dirty, oily, or rusty steel. The high silicon content increases the fluidity of the weld pool, thus creating a smoother bead appearance and resulting in minimal post-weld grinding

UNIMIG ER70S-6 wire is engineered to provide porosity-free, x-ray quality welds at the highest tensile strength (as welded) of all the plain carbon steel wires. ER70S-6 Solid MIG Wire requires a shielding gas: CO² and/or CO² mix. UNIMIG ER70S-6 wire is Precision Layer Wound for smooth uninterrupted wire feed with less liner and tip wear.

Typical Applications

- Structural Steel

- General Fabrication

- Light Fabrication

- Transport Industry

- Heavy Equipment

- Farm Machinery Pressure Vessels

- Robotic and Semi-Automatic Welding Applications

| FEATURES: |

|---|

| – UNIMIG ER70S-6 Mild Steel MIG Welding Wire |

|

– This wire performs exceptionally well for general steel construction, sheet metal applications, pressure vessel applications, structural welding and pipe welding.

|

|

– S6 is a versatile mild steel welding wire that produces quality weld results even when used on dirty and contaminated steel. Although this is not recommended, it is due to the wire containing higher levels of manganese and silicon than S2 and S4.

|

|

– High-quality, copper-coated, triple de-oxidised solid MIG welding wire supplied on 15kg, 5kg and 1Kg precision layer wound plastic spools.

|

|

– The wire contains higher levels of manganese and silicon than most standard grades of MIG wire to produce high-quality welds.

|

|

– The high silicon content increases fluid in the weld pool which in turn, produces a smooth bead appearance.

|

|

– The wire is engineered to provide porosity-free, x-ray quality welds with high tensile strength.

|

|

– Precision Layer Wound for smooth uninterrupted wire feed with less liner and tip wear.

|

|

– ER70S-6 Solid MIG Wire requires a shielding gas such as CO² or Argon/CO² mixes.

|

|

– Applications: Structural Steel, General Fabrication, Light Fabrication, Transport Industry, Heavy Equipment, Farm Machinery Pressure Vessels, Robotic and Semi-Automatic Welding Applications

|

- High Quality

- Triple De-oxidised

- X-Ray Quality

- Precision Layer Wound

- Smooth Feeding

- Clean Weld Finish

- International Approvals

- ER70S-6

- AS/NZS 2717.1:ES6 – CG – W503H

APPROVALS 5KG AND 15 KG SPOOLS

- LLOYDS REGISTER

- DET NORSKE VERITAS

- AMERICAN BUREAU OF SHIPPING