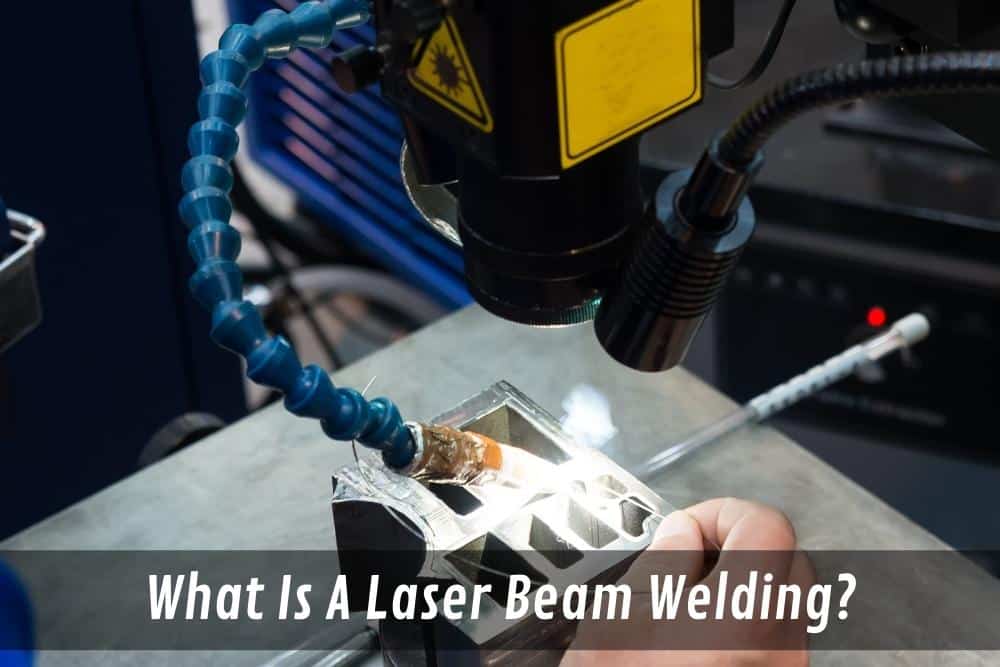

Do you know anything about a laser welding machine? Have you ever wondered how some of your favourite products are made? From cars to jewellery, there are various welding techniques utilised to produce them. One such method is laser beam welding, but what exactly is it?

Laser beam welding is performed using a specialised machine with a welding head and high-voltage source. The power of the laser beam is proportional to the amount of power supplied to it, so the intensity of the weld can be adjusted depending on what materials need to be joined. It’s also important to consider the location of the focal point and spot size when setting up for this type of welding.

The process itself involves focusing the laser beam onto a small area where heat is generated, melting and fusing two pieces together. This produces a weld that’s characterised by its small heat-affected zones, meaning there’s very little distortion or warping on either side of the joint. Additionally, laser beam welding has incredibly fast speeds, making it ideal for materials that are difficult to join.

In this article, we will explore the ins and outs of laser beam welding, including the functions ad various types of laser beam welding machines. Whether you’re a manufacturing professional or simply curious about the mechanics behind some of your favourite products, read on to learn more about this cutting-edge technology.

Types of Lasers Used in Laser Beam Welding

There are three main types of lasers used in laser beam welding today: gas, solid state, and CO2 lasers.

- Gas laser welding typically has the highest power output and can be used for thicker materials.

- While solid-state lasers tend to have a lower power output and are more suitable for thinner materials.

- High power cO2 lasers are most commonly used in the automotive industry because they produce very clean welds with minimal distortion.

- In addition, fibre laser technology is also becoming increasingly popular due to its high precision and efficiency.

What are the various types of laser beam welding machines available?

There are several types of laser beam welding machines available, including:

- CO2 Laser Welding Machines: The utilisation of a carbon dioxide laser welding machine is a prevalent practice in industrial settings, as it allows for the joining of a variety of materials, including metals, plastics, and ceramics.

- ND YAG Laser Welding Machines: YAG lasers have numerous applications in welding, specifically in the welding of thin materials such as jewellery and electronic components, as well as spot and seam welding of metals.

- Fibre Laser Welding Machines: These fibre-optic laser machines are multi-functional and can be used for welding various metals such as stainless steel, copper, and aluminium, as well as for precise cutting and marking applications.

- Diode Laser Welding Machines: Diode lasers are used in welding and soldering small components, particularly for electronics and medical equipment.

- Pulsed Laser Welding Machines: Pulsed laser welding machines are widely used for precise welding demands, particularly within industries such as aerospace where stringent control is paramount.

- Continuous Wave Laser Welding Machines: Continuous wave laser beam machines are frequently used in high-speed welding applications, particularly in the automotive industry, to effectively weld materials.

The choice of laser welding machine will depend on the specific application, the materials being welded, and the desired welding characteristics.

What are their components?

The composition of a laser beam welding machine may fluctuate based on the precise type and model; however, typically, the following components are included.

- Laser Source: The laser source is the driving power behind the beam and can be either a gas laser, solid-state laser, or fibre laser. The intensity of the beam generated by the source is proportional to the amount of power supplied.

- Optics: The optical system is the component that focuses the laser beam to a specific spot size, usually somewhere between 0.1 and 0.2 millimetres in diameter. The optics also determine where the focal point of the beam will be located.

- Workpiece Holding Fixture: This fixture holds the materials being welded in place and ensures that the laser beam is properly aligned.

- Control System: The control system regulates the power of the beam, the welding speed and duration, as well as the type of welding process. It also contains safety features to ensure that the laser does not cause any damage to people or objects.

- Cooling System: The laser source and other components generate a large amount of heat during operation, so the cooling system keeps temperatures under control and prevents damage to the machine.

- Safety System: Laser Beam Welding (LBW) machines can be dangerous if used improperly, so the safety system includes protective measures such as a high-voltage protector and access lockout to prevent unauthorised operation.

- Gas Delivery System: Depending on the materials being welded, a gas delivery system may be used to protect the weld pool from oxidation or contamination.

The integration of these components culminates in the formation of a high-energy laser beam, allowing for the precise welding of diverse materials with a remarkable level of speed and accuracy, while simultaneously minimizing the size of the heat-affected zone.

Conclusion

Overall, the laser beam welding machine provides a high-precision, high-speed, and high-quality welding solution for a wide range of materials and applications, and is widely used in the aerospace, automotive, medical, and electronics industries. Additionally, some of the best welding machine brands offer LBW machines with a range of features, allowing you to customise your welding process to meet the specific needs of your application.

If you have any questions about which laser beam welding machine is right for your needs, the team at Electroweld can help. We offer a wide range of laser beam welding machines to suit any application, as well as expert advice to ensure that you make the right decision. We also provide different types of welding machines and accessories to further enhance your welding process. Contact us today to get started.